RECALL

In a circular economy context, the interdisciplinary RECALL project aims to develop sustainable processes to recover iron and critical metals from bauxite residues while exploring the economic impact of the developed process in terms of social welfare where potential environmental and health impacts are taken into account.

Issues

With a world population estimated to exceed 9 billion in 2050, the demand for raw materials is growing rapidly. In this context, the European Commission has identified a number of materials facing specific challenges. Among these, access to certain raw materials (including critical metals) has been identified as a growing global concern in the face of complex geostrategic conflicts. A shortage of these materials could hinder the deployment of a number of strategic technologies, including digital and renewable energies which contain many critical metals, including rare earth elements.

Beyond critical metals, all mineral resources are facing an unprecedented increase in demand, including base metals, underlining the urgent need to identify sustainable mining strategies that preserve natural reserves and the environment. A paradigm shift is needed to identify alternative sources and extraction strategies. In particular, in the context of a circular economy, there is an urgent need to produce these critical metals from secondary sources such as end-of-life products, mine tailings, municipal and industrial waste.

Among the secondary sources, electronic waste has been the subject of much research as it often contains high concentrations of critical metals. Although less studied, mining and industrial wastes contain lower critical concentrations but are produced in such large volumes that the extraction of the critical metals they contain could more than meet current annual demand. For example, it is estimated that the annual global production of bauxite residues from alumina production is about 150 million tonnes. With an average rare earth concentration of about 1,000 mg/kg in bauxite residues, about 150,000 tonnes of these metals could be extracted each year, which is more than the global production in 2016 (126,000 tonnes).

Objectives

In a circular economy context, the interdisciplinary RECALL project aims to develop sustainable processes to recover iron and critical metals (rare earths, gallium and scandium) from bauxite residues while exploring the economic impact of the developed process in terms of social welfare in which potential environmental and health impacts are taken into account.

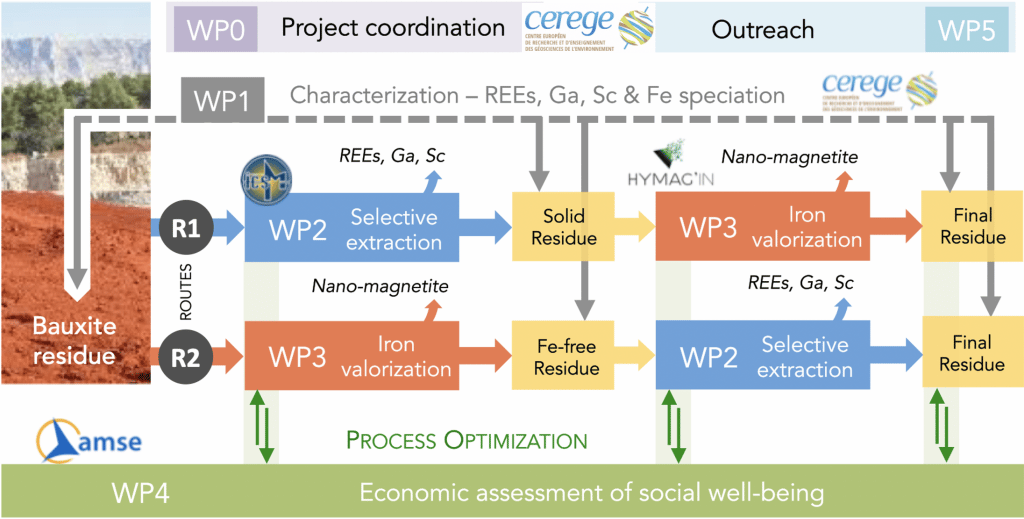

The RECALL project is based on five Work Packages (WP) which aim to develop sequential extraction processes for critical metals (WP2) and iron (WP3) based on an in-depth characterisation of the residues at different stages of the process (WP1).

Natural biomolecule proxies will be used as extractants under mild conditions. WP4 will quantify the reduction of negative externalities (e.g. environmental and health impacts of the process we will develop) compared to traditional hydro-pyro-metallurgical protocols, and will guide the processes developed in WP2 and WP3 via feedback loops.

We believe that taking into account social welfare, which goes far beyond the technical performance of the process, will pave the way for the industrial valorisation of a controversial waste that is currently little or not valorised. In particular, we believe that this interdisciplinary approach will allow us to better anticipate market problems that could prevent the technology from gaining momentum.

Finally, WP5 proposes, among other things, an innovative awareness-raising action towards society with the design and construction of an exhibition module on the concept of the "urban mine" as part of a general public exhibition on the circular economy.

2021-2025: RECALL

Sustainable extraction of valuable metals from bauxite tailings

Financing : ANR

Head of CEREGE :

Clément Levard

Partners :

- HYMAG'IN, Grenoble

- ICSM Institut de Chimie Séparative de Marcoule, Marcoule

- AMSE Aix Marseille School of economics, Marseille